Greenhouse gas emissions have become a defining challenge of our time, contributing to global climate change and environmental instability. Industries that rely on heavy manufacturing, fossil fuel consumption, and large-scale energy use account for a significant share of these emissions.

Reducing greenhouse gases is not just an environmental responsibility — it’s an operational necessity. By adopting sustainable practices, optimizing energy use, and investing in efficient equipment, organizations can significantly lower their carbon footprint while maintaining productivity and profitability.

This article explores the major sources of greenhouse gases and highlights practical, technology-driven strategies industries can adopt to minimize their emissions and move toward a more sustainable future.

Understanding Greenhouse Gas Emissions

Greenhouse gases, such as carbon dioxide (CO₂), methane (CH₄), and nitrous oxide (N₂O), trap heat in the Earth’s atmosphere, leading to global warming. Industrial sectors are among the largest contributors due to their reliance on combustion processes, energy-intensive machinery, and material manufacturing.

Major industrial emission sources include:

-

Fossil Fuel Combustion: For power generation and heat.

-

Chemical Processing: Especially in fertilizer, cement, and metal production.

-

Manufacturing Equipment: Inefficient or outdated systems contribute to energy waste.

-

Transportation and Logistics: Fuel-powered systems used for product distribution.

Understanding these emission pathways allows businesses to design targeted strategies to reduce them without compromising performance.

1. Improving Energy Efficiency

Energy efficiency remains the most direct and impactful way to reduce GHG emissions. When industries consume less energy for the same output, they lower both their carbon footprint and operating costs.

Key measures include:

-

Upgrading Equipment: Replacing old or energy-inefficient machinery with modern, optimized alternatives.

-

Automation and Smart Controls: Utilizing transmitters and sensors to monitor performance and eliminate energy wastage.

-

Heat Recovery Systems: Capturing waste heat and reusing it for other processes.

-

LED and Smart Lighting Systems: Reducing energy use in industrial facilities.

Even incremental efficiency improvements across equipment and utilities can yield significant reductions in emissions over time.

2. Transitioning to Renewable Energy Sources

Switching from fossil fuels to renewable energy is one of the most transformative solutions to mitigate industrial emissions. Solar, wind, and hydroelectric power eliminate or drastically reduce CO₂ output from power generation.

For industries, this transition can involve:

-

Installing on-site renewable energy systems (solar panels, wind turbines).

-

Purchasing green electricity through power purchase agreements (PPAs).

-

Using hybrid systems that combine renewable sources with traditional energy for continuous supply.

Renewable energy adoption not only cuts emissions but also provides long-term cost stability against fluctuating fuel prices.

3. Implementing Carbon Capture and Storage (CCS)

Carbon Capture and Storage (CCS) technology is an advanced method that captures CO₂ emissions from industrial sources before they enter the atmosphere. The captured carbon is then either stored underground or used for other industrial applications such as enhanced oil recovery.

Although still developing, CCS is gaining traction in industries like cement production, chemical refining, and power generation. Integrating such systems allows companies to maintain production capacity while achieving substantial emission reductions.

4. Optimizing Process and Equipment Performance

Industrial efficiency heavily depends on the performance of equipment such as transmitters, valves, pumps, and sensors. Instruments that operate below optimal levels can cause excessive energy consumption and emissions.

Regular calibration, condition monitoring, and timely replacement of outdated components play a vital role in maintaining efficiency. Many facilities now rely on advanced process transmitters that monitor pressure, flow, and temperature in real time to ensure consistent performance and reduced waste.

By keeping systems in peak condition, industries not only extend equipment life but also prevent unnecessary emissions caused by inefficiency.

5. Reducing Methane Leaks and Fugitive Emissions

Methane is over 25 times more potent than CO₂ as a greenhouse gas. In oil, gas, and petrochemical facilities, fugitive methane emissions often occur through leaks in pipelines, valves, and storage systems.

Industries can address this by:

-

Conducting regular leak detection and repair (LDAR) inspections.

-

Installing smart sensors for continuous emission monitoring.

-

Using sealed components and high-integrity gaskets to prevent leakage.

-

Adopting best practices for handling, storage, and transportation of hydrocarbons.

Preventing even small leaks leads to measurable improvements in overall emission control.

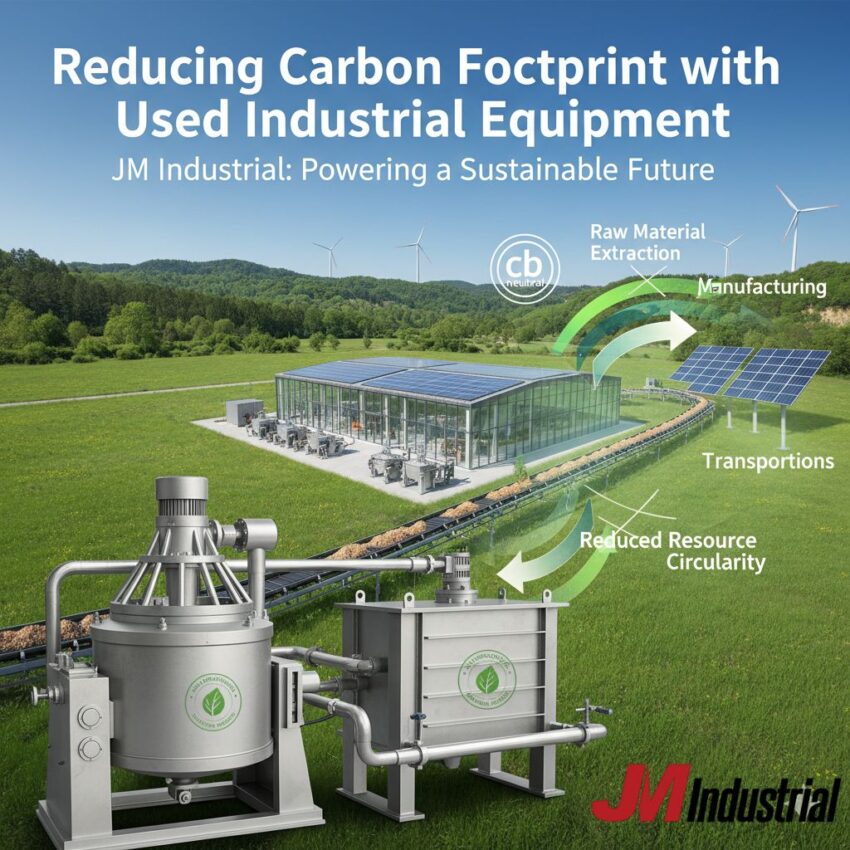

6. Adopting Circular Economy Practices

A circular economy approach focuses on minimizing waste by reusing, remanufacturing, and recycling materials and equipment.

In the context of industrial operations, this can include:

-

Using Reconditioned and Remanufactured Equipment: Such as transmitters, valves, and control devices that perform like new but require far less energy to produce.

-

Recycling Process Waste: Recovering and reusing materials like metal, water, or solvents.

-

Extending Equipment Life Cycles: Through refurbishment and recalibration instead of disposal.

Circular economy principles reduce the need for new resource extraction and manufacturing, which in turn cuts emissions from production and logistics.

7. Enhancing Data Monitoring and Emission Tracking

Data-driven decision-making is at the heart of effective emission reduction. By deploying smart instrumentation and monitoring systems, industries can measure, track, and optimize their carbon output in real time.

Modern monitoring technologies include:

-

Advanced Transmitters: For pressure, temperature, and flow control to maintain energy efficiency.

-

SCADA and IoT Systems: For centralized monitoring and analysis.

-

Predictive Analytics: To identify inefficiencies before they lead to increased emissions.

Digitalization enables industries to take proactive measures rather than reactive corrections, ensuring sustained improvement in energy and emission performance.

8. Promoting Employee Awareness and Sustainable Culture

Technology and process improvements alone cannot achieve lasting emission reductions without cultural change. Building awareness among employees, encouraging responsible resource use, and fostering sustainability-focused mindsets can create lasting impact.

Organizations can promote sustainability by:

-

Training employees in energy conservation practices.

-

Setting clear sustainability goals and reporting progress.

-

Incentivizing innovation and eco-friendly initiatives.

A workforce aligned with sustainability objectives ensures consistent, organization-wide participation in emission reduction efforts.

9. Regulatory Compliance and Incentives

Many governments now offer regulatory frameworks and incentives for emission reduction. Industries can benefit from tax credits, renewable energy subsidies, and carbon offset programs by aligning with national or international sustainability goals.

Compliance not only helps avoid penalties but also enhances brand reputation and stakeholder trust. Proactively participating in sustainability programs demonstrates an organization’s commitment to environmental stewardship.

10. Investing in Research and Innovation

Continuous innovation is essential for long-term emission reduction. Industries are increasingly collaborating with technology developers and research institutions to create next-generation solutions — such as advanced catalytic systems, green hydrogen energy, and improved material efficiency.

By staying ahead of technological developments, organizations can achieve deeper carbon cuts while maintaining competitive advantage.

Conclusion

Reducing greenhouse gas emissions is no longer an option — it’s a necessity for long-term industrial sustainability and global environmental balance. Through energy efficiency, renewable energy adoption, process optimization, and circular economy practices, industries can make meaningful progress toward achieving net-zero goals.

The Transmitter Shop supports this transition by providing precision-tested transmitters and instrumentation that help industries optimize performance and reduce energy waste. When facilities operate efficiently, they not only cut emissions but also enhance reliability and cost-effectiveness — proving that sustainability and productivity can go hand in hand.