After working for more than 25 years as a Thermal Engineer across India and the US, one truth has stayed consistent: the performance of your heating system depends heavily on the quality of your heating coil. When industries rely on precision manufacturing, the decision to choose the right heating coil manufacturers in india becomes critical—not a routine procurement step.

Industrial hubs like Bangalore, Pune, Chennai, and Hyderabad are increasingly adopting automation, high-accuracy moulding, semiconductor tooling, and medical device production. All of these require heaters that offer stability, repeatability, and long operational life. And yet, many companies still underestimate how a poorly engineered coil can cause thermal imbalance, part rejection, and extended downtime.

This article explains the engineering principles that separate reliable heaters from unreliable ones, based on real field experience rather than catalogue descriptions.

The Hidden Cost of Cheap Heating Coils

In one Bangalore-based packaging plant, a hot runner machine kept failing despite frequent coil replacements. The issue was not wear and tear—the problem was cheap coils produced by a vendor who claimed to be a manufacturer but was merely a small assembler reshaping imported coils.

Cheap coils fail early because cheap materials fail early.

Common failure reasons include:

- Low-purity magnesium oxide insulation

- Inferior nichrome alloys that drift under temperature

- Inconsistent winding pitch causing hotspots

- Poor compaction creating internal air pockets

- Untreated sheaths prone to cracking

A coil’s wattage rating rarely predicts its performance. What matters is how the heater is built—its insulation purity, alloy specifications, compaction density, and thermal uniformity.

This is why genuine heating coil manufacturers in india focus heavily on quality control rather than price-driven shortcuts.

Why Bangalore Depends on custom heating elements

If there is one lesson Bangalore’s manufacturing ecosystem teaches, it is this: precision requires customization.

From aerospace research to medical device assembly to intricate moulds in Peenya and Bommasandra, modern industries rely on custom heating elements engineered for:

- Exact watt density distribution

- Specific sheath temperatures

- Precise bending geometry

- Fast ramp-up response

- Long cycle durability

A skilled coil heaters manufacturer understands how a heater interacts with the tooling, melt flow, or component being heated. Standard catalogue heaters may fit in size, but they rarely deliver the thermal behavior required for high-accuracy applications.

Over the years, I’ve seen production lines improve simply by replacing standard coils with properly designed custom heating elements that match the tool’s thermal map.

The Heating Ecosystem Matters More Than the Coil Alone

One recurring mistake across Indian factories is assuming heater failure is caused only by the heater. In reality, most heater failures originate from errors in the surrounding heating ecosystem.

A heater is only one piece of the thermal chain. The other critical components are:

- Temperature controllers

- Thermocouples

- Power regulation systems

- Sensor placement

- Insulation and clamping method

You can install the best heater possible, but if the controller is poorly tuned, the coil will overheat. If the thermocouple is misaligned, the heater will constantly try to correct inaccurate readings. If the power supply fluctuates, the coil will experience stress cycles that reduce life.

This is why experienced manufacturers don’t just produce heaters—they guide engineers through complete Heating Solutions that involve controller tuning, sensor optimization, and load balancing.

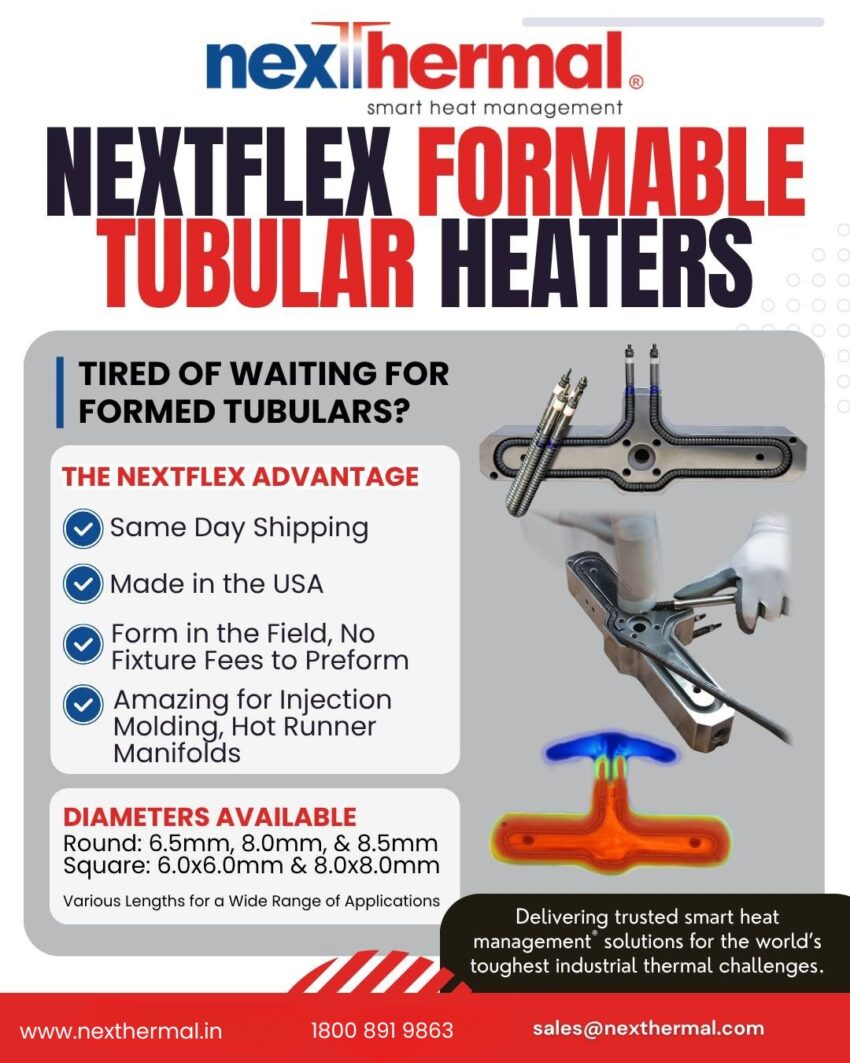

Hot Runner Systems: Precision Makes or Breaks the Process

Hot runner moulding is one application where coil engineering quality is immediately visible. Melt temperature must remain consistent across the nozzle, and even a small thermal variation can cause part defects, gate burning, or flow imbalance.

A dependable Coil Nozzle Heater manufacturer understands:

- How closely the heater must wrap around the nozzle

- The correct watt density for the melt type

- Radial and axial heat uniformity

- Response time for temperature corrections

- Long-term resistance stability

In one moulding shop in Bangalore, a nozzle defect was blamed on tooling design, but the actual problem was a coil with inconsistent winding pitch that caused a 40°C hotspot. Precision engineering—not guesswork—solves problems like these.

This is why companies choose manufacturers with deep expertise in nozzle heating rather than low-cost assemblers who cannot control winding, compaction, or insulation quality.

What Separates True Manufacturers from Assemblers

India has many heater vendors, but only a small percentage are genuine manufacturers. The rest are assemblers, reshaping imported coils and selling them without proper testing or engineering control.

A true coil heater element manufacturer offers:

- In-house winding with precise pitch control

- High-density MgO compaction

- CNC bending and shaping accuracy

- Thermal cycling and insulation resistance testing

- Consistent alloy and sheath quality

- Traceability for every production batch

Assemblers cannot replicate this because they lack machinery, testing equipment, and engineering discipline. And this is what ultimately affects your heater’s life, stability, and performance.

Companies with high uptime requirements—pharma, plastics, aerospace, semiconductor, FMCG—understand this difference immediately.

The Future: Predictive Maintenance and Engineering Partnerships

Modern heating systems are moving toward predictive analysis rather than reactive replacement. Experienced teams can look at resistance drift, heat-up time, and load imbalance to predict failures weeks before they occur.

A reliable manufacturer becomes a long-term engineering partner, helping you:

- Diagnose hotspots

- Tune your controllers

- Improve thermocouple placement

- Select the correct sheath material

- Build a preventive maintenance strategy

As industries move toward automation and continuous processes, heater reliability becomes more than a technical requirement—it becomes a competitive advantage.

Conclusion: Why Experience Still Defines the Best heating coil manufacturers in india

India’s industrial landscape is evolving rapidly, especially in technology-driven cities like Bangalore. The companies leading this transformation are those that prioritize engineering depth, material science, and thermal accuracy over catalogue selling.

The difference between a heater that lasts 3 weeks and one that lasts 3 years is not luck—it is engineering.

Choosing the right heating coil manufacturers in india is a decision that affects uptime, safety, efficiency, and profitability. And in high-precision environments, it is expertise—not price—that ultimately determines success.

Call us: 1800 891 9863

Book a Consultation: https://www.nexthermal.in/

Visit Product Page: https://www.nexthermal.in/coil-heaters/

Connect With Us

More Products:

Electric Heating Elements manufacturer | cartridge heating element | coil heaters manufacturer | temperature sensors manufacturer | tubular heaters manufacturer | temperature controller manufacturers | Engineering services provider in india | Ceramic Infrared Heater manufacturer |Temperature Control Panel manufacturer | Heating Coil Element manufacturer | Tubular Heater manufacturer | Temperature Sensors manufacturer | Temperature Controller manufacturer