Chlorthalidone Manufacturer: Understanding Production, Quality Standards & Global Demand

Chlorthalidone is a widely used thiazide-like diuretic prescribed for managing hypertension and edema. As global health systems continue to prioritize cardiovascular care, the demand for this essential Active Pharmaceutical Ingredient (API) has grown steadily. Behind its availability lies a sophisticated manufacturing process that requires strict quality control, regulatory compliance, and advanced pharmaceutical capabilities.

This blog explores how Chlorthalidone manufacturers operate, what goes into producing the API and finished dosage forms, and what buyers should look for when sourcing it.

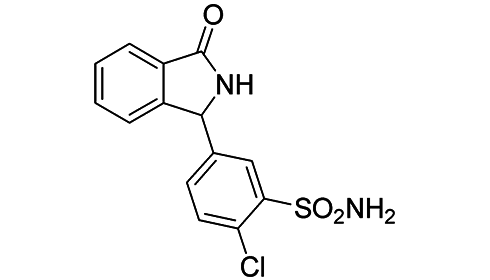

What Is Chlorthalidone?

Chlorthalidone is a long-acting diuretic often used for:

- Managing high blood pressure

- Treating fluid retention (edema)

- Supporting heart failure treatment

- Reducing risks associated with cardiovascular complications

Its long half-life and proven clinical effectiveness have made it an important medication in global health programs.

How Chlorthalidone Is Manufactured

Manufacturing Chlorthalidone involves a series of chemical synthesis steps, purification processes, and stringent quality checks. The process can be divided into:

1. API Synthesis

Producers synthesize the Chlorthalidone API using:

- Controlled reactions between benzene-based intermediates

- Use of catalysts and reagents

- Strict temperature and pH monitoring

Each stage must be validated to ensure consistency and compliance.

2. Purification & Crystallization

Once synthesized, the API undergoes:

- Filtration

- Recrystallization

- Drying

Manufacturers must maintain impurity levels within pharmacopeial limits (USP, EP, IP, etc.).

3. Granulation & Formulation (for Finished Dosage Forms)

If the manufacturer produces tablets, the next step includes:

- Granulating the API with excipients

- Compressing tablets using high-precision machinery

- Coating (if applicable)

- Packaging under controlled environments

Quality Standards Followed by Chlorthalidone Manufacturers

To be globally compliant, manufacturers adhere to regulatory guidelines such as:

- Good Manufacturing Practices (GMP)

- ISO Quality Certifications

- Pharmacopeial Standards (USP, BP, IP, EP)

- Regulatory approvals like USFDA, EMA, MHRA, and WHO-GMP

Routine analytical tests include:

- Assay analysis

- Impurity profiling

- Stability studies

- Dissolution testing for tablets

These standards ensure product safety, efficacy, and purity.

Global Demand for Chlorthalidone

The demand for Chlorthalidone continues to increase due to:

- Rising hypertension cases worldwide

- Growing adoption in national health programs

- Increased recognition of Chlorthalidone as a first-line therapy

- Expanded generic production in emerging markets

Manufacturers serving these markets must maintain consistent supply chains to meet global needs.

What Buyers Look for When Choosing a Chlorthalidone Manufacturer

Whether sourcing API or finished tablets, buyers evaluate manufacturers based on:

1. Regulatory Compliance

Approvals and audits demonstrate product integrity.

2. Manufacturing Capacity

Large-scale production ensures uninterrupted availability.

3. Quality Control Systems

Advanced labs and validated processes are crucial.

4. Supply Chain Reliability

Timely delivery, transparent communication, and efficient logistics matter significantly.

5. Cost Efficiency

Competitive pricing without compromising quality remains a priority.

The Future of Chlorthalidone Manufacturing

As hypertension continues to be a major global health challenge, manufacturers are expected to:

- Upgrade technologies for cleaner and more efficient synthesis

- Expand production to meet rising international demand

- Strengthen research on improved formulations

- Implement greener and more sustainable manufacturing practices

Final Thoughts

Chlorthalidone manufacturers play a vital role in ensuring that this life-saving medication remains accessible, affordable, and high in quality. From complex chemical synthesis to regulated production environments, the journey of Chlorthalidone from factory to pharmacy involves a high level of expertise and compliance.

URL: For more information, visit Enanti Labs : Chlorthalidone Manufacturer