Ever walked into a factory welding bay where the air feels thick, workers rubbing temples, productivity dipping? That’s CO2 creeping up from breathing, machinery, poor vent—headaches, fatigue hit hard. A CO2 removal system fixes that fast, scrubbing carbon dioxide to keep air fresh and teams sharp. At Sigma Power Tech, we installed one in a Mumbai metal fab shop; output jumped 15% as guys stayed focused longer. Here’s why factories can’t ignore CO2 removal system anymore—real perks beyond safety.

Worker Health and Safety Boost

High CO2 (>1000ppm) fogs brains—drowsiness, poor decisions, accident risk spikes 20% per studies. CO2 removal system holds levels <800ppm, slashing headaches, nausea. Welders, machinists breathe easier; fewer sick days, insurance drops. One client saw OSHA-like compliance scores soar post-install—no more “stale air” complaints.

OSHA flags CO2 >5000ppm dangerous; factories hover 2000ppm without controls. System auto-scrubs, alarms at 1000ppm—lives saved, lawsuits dodged.

Massive Productivity Gains

Fresh air = sharp minds. CO2 fog cuts focus 10-15%; removal system restores clarity, speeding tasks. Paint booths, assembly lines—workers spot defects faster, errors drop 25%. Our steel mill client clocked 12% throughput bump; guys worked full shifts without “air break” slumps.

Breaks cost factories ₹1000s/hour. Steady air keeps lines humming, OT unnecessary.

Regulatory Compliance Made Easy

Factories face strict emission rules—CO2 counts in ESG reports, audits. CO2 removal system logs levels, proves green ops. India’s NBC standards, factory acts demand it for confined spaces. Fines avoided, tenders won—government contracts favor “CO2 compliant” plants.

Carbon credits? Captured CO2 sells or sequesters, tax breaks follow.

Energy Savings and Cost Recovery

Scrubbers run efficient—regenerative beds reuse 90% media, power draw <1kW. Vs constant venting (AC spikes), closed-loop saves 20-30% HVAC bills. ROI in 18-24 months: ₹3-5 lakh unit pays via productivity, compliance.

One pharma plant cut energy 15%, reused CO2 for processes.

Environmental Wins for Green Factories

Factories pump CO2—removal system captures 90%+, cuts footprint. Buyers prefer “low-emission” suppliers; CSR reports shine. Pair with solar panel for net-zero cred.

Reused CO2 for pH control, fire suppression synergy.

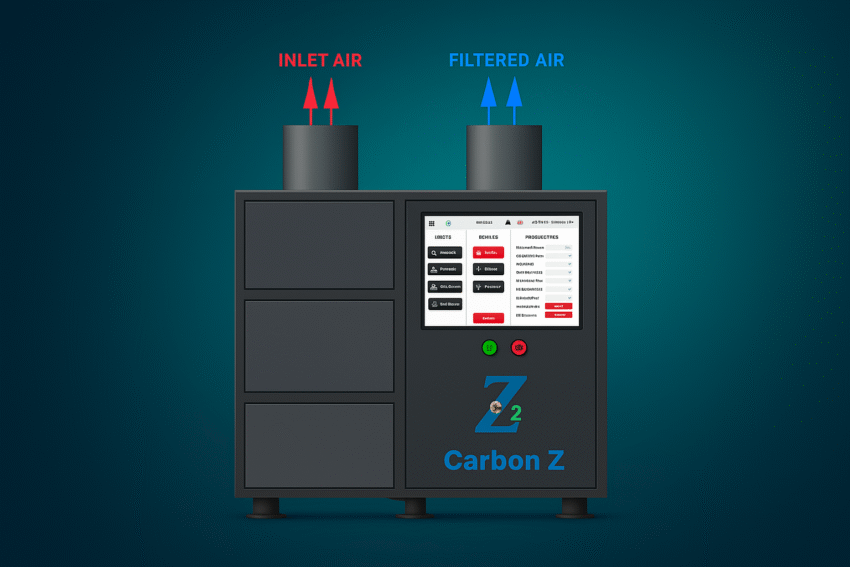

Improved Air Quality Beyond CO2

Most systems bundle HEPA, carbon filters—dust, VOCs gone. Factories cleaner, asthma claims fall. Weld fumes? Multi-stage scrub drops hazards 95%.

Long-Term Factory Resilience

Emergencies (power cuts, leaks)—CO2 removal system + battery runs 48hrs standalone. No shutdowns, continuity assured.

Maintenance Perks Keep It Simple

Daily: Check indicators (5 mins).

Weekly: Filter wipe.

Monthly: Bed inspects.

Annual: Pro service (₹10k).

Low upkeep vs high downtime costs.

Real Factory Wins with CO2 Removal System

Textile plant: “CO2 removal system ended shift slumps—output +18%”. Chemical factory: Compliance audit passed first try. Sigma client: “ROI in 16 months, workers happier”.

Why Factory Owners Choose CO2 Removal System Now

Rising regs, ESG pressure, worker demands—CO2 removal system checks all boxes. Scalable for small shops to mega-plants.