The pharmaceutical industry in India has gained global recognition for producing high-quality APIs and finished formulations at competitive prices. Among the widely used cholesterol-lowering drugs, Ezetimibe holds a significant position. Today, Ezetimibe manufacturers in India follow advanced, compliant, and well-regulated production systems to meet growing domestic and international demand. Understanding the step-by-step manufacturing process helps buyers, importers, and pharmaceutical partners assess quality, reliability, and compliance standards.

Introduction to Ezetimibe Production in India

Ezetimibe is an antihyperlipidemic drug used primarily to reduce intestinal cholesterol absorption. Indian pharmaceutical companies manufacture Ezetimibe under strict quality frameworks such as WHO-GMP, ISO, and other global regulatory standards. The production process focuses on purity, consistency, and scalability, which has positioned India as a preferred sourcing destination for Ezetimibe API and finished dosage forms.

Step 1: Raw Material Sourcing and Verification

The manufacturing process begins with sourcing high-quality raw materials and intermediates. Reputed suppliers are selected to ensure chemical consistency and traceability. Each incoming raw material undergoes identity testing, purity analysis, and documentation checks before approval. This step is crucial, as the final quality of Ezetimibe depends heavily on the integrity of its starting materials.

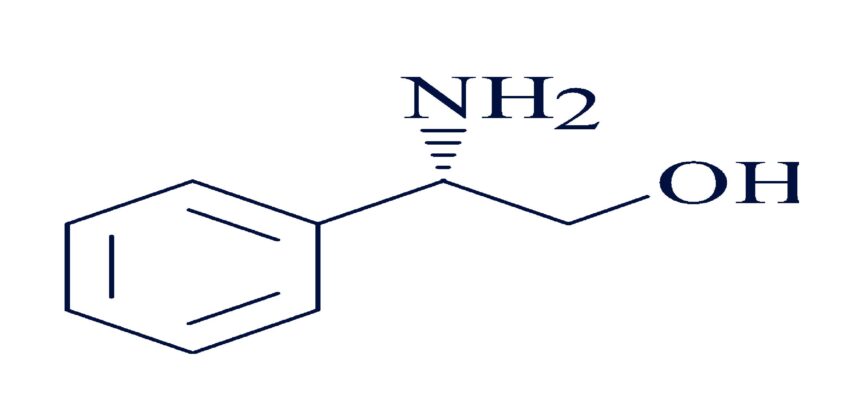

Step 2: Chemical Synthesis of Ezetimibe API

Ezetimibe is produced through a multi-step chemical synthesis process. Controlled reactions are carried out under specific temperature, pressure, and pH conditions. Advanced reactors and automated systems are used to minimize deviations and ensure reproducibility. Indian pharmaceutical manufacturers invest heavily in R&D and process optimization to improve yields while maintaining regulatory compliance.

Step 3: Reaction Monitoring and Process Control

Throughout synthesis, in-process quality control checks are conducted. Parameters such as reaction completion, impurity profile, and molecular structure are monitored using validated analytical methods. This stage ensures that the intermediate compounds meet predefined specifications before moving to the next phase.

Step 4: Isolation and Purification

Once synthesis is complete, the crude Ezetimibe API is isolated and purified using filtration, crystallization, and washing techniques. Purification is critical to remove residual solvents, by-products, and impurities. This step significantly impacts the safety and efficacy of the final product, especially for regulated export markets.

At this stage, Ezetimibe manufacturers in India demonstrate their technical expertise by maintaining consistent purity levels across batches.

Step 5: Drying and Milling

After purification, the Ezetimibe API is dried under controlled conditions to achieve the required moisture content. Drying parameters are carefully monitored to prevent degradation. The dried API is then milled to obtain uniform particle size, which is essential for formulation performance and bioavailability.

For pharmaceutical buyers and importers seeking reliable sourcing, Ezetimibe manufacturers in India continue to be trusted partners offering consistency, regulatory assurance, and long-term value.

Step 6: Quality Control and Analytical Testing

Comprehensive quality testing is conducted on the final API batch. This includes identification, assay, impurity profiling, residual solvent analysis, and stability testing. Indian manufacturers use sophisticated instruments such as HPLC, GC, and IR spectroscopy to ensure compliance with pharmacopeial standards.

Step 7: Packaging and Storage

Approved Ezetimibe API is packed in pharmaceutical-grade containers that protect it from moisture, light, and contamination. Proper labeling, batch numbering, and documentation ensure full traceability. Storage conditions are maintained as per regulatory guidelines to preserve product stability until dispatch.

Step 8: Regulatory Compliance and Documentation

One of the strengths of Ezetimibe manufacturing in India is strict adherence to regulatory requirements. Manufacturers maintain complete batch manufacturing records, certificates of analysis, and validation documents. This makes Indian suppliers reliable partners for global pharmaceutical companies seeking compliant and export-ready products.

Why India Is a Preferred Hub for Ezetimibe Manufacturing

India offers a unique combination of cost efficiency, skilled workforce, advanced infrastructure, and regulatory expertise. Ezetimibe manufacturers in India supply both API and finished formulations to markets across Asia, Europe, Africa, and Latin America. Their ability to scale production while maintaining quality makes them competitive in the global pharmaceutical supply chain.

Conclusion

The step-by-step manufacturing process of Ezetimibe in India reflects the country’s commitment to quality, compliance, and innovation. From raw material selection to final packaging, every stage is carefully controlled to meet international standards.

Other Recommendations: Vonoprazan Fumarate API manufacturers in India