In every industry, one thing stays the same — the need to move fluids smoothly and without interruption. Whether it’s oil, chemicals, or other liquids, the process must be efficient and reliable. That’s where Rotary Gear Pumps come into play. These pumps are small in size but mighty in performance. They help industries work faster, save time, and cut down on waste. In this blog, we’ll explore how Rotary Gear Pumps help improve productivity and reliability in different industrial settings.

Understanding the Rotary Gear Pump

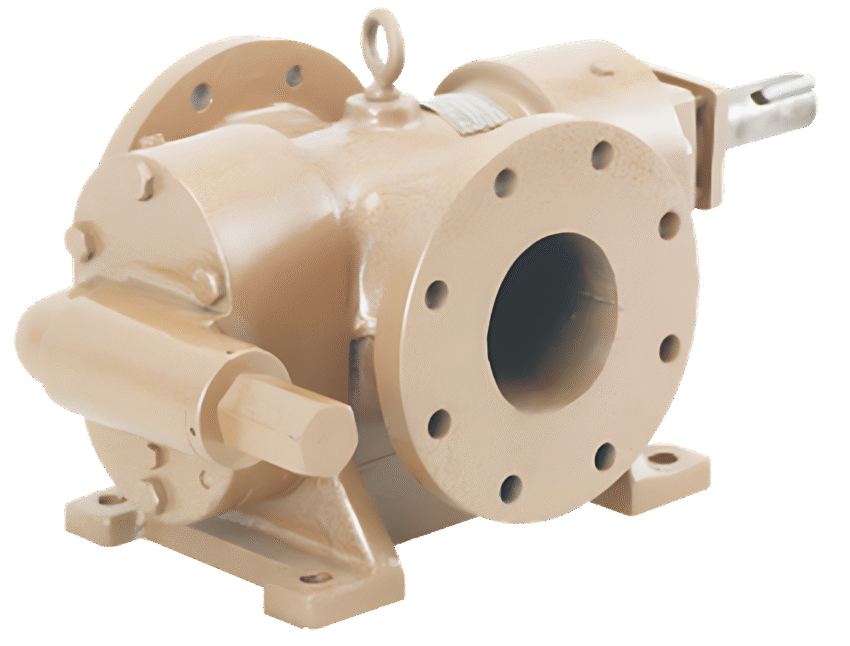

A Rotary Gear Pump is a simple yet powerful device used to move liquids from one place to another. It works using two gears that rotate together inside a casing. When the gears turn, they trap liquid between their teeth and push it forward. This smooth and steady motion makes sure the fluid keeps flowing evenly without sudden stops or jerks.

The beauty of a Rotary Gear Pump lies in its simplicity. It doesn’t need complex parts or heavy maintenance. Once installed, it just keeps working quietly in the background. That’s why many industries trust these pumps for day-to-day operations.

Why Industries Prefer Rotary Gear Pumps

Every factory or plant depends on reliable machines. A breakdown can cause hours of delay and cost huge amounts of money. The Rotary Gear Pump helps prevent this. Because of its simple design and strong build, it can handle continuous work without overheating or losing pressure.

Industries that deal with oils, fuels, or chemicals find these pumps extremely useful. The pump’s steady pressure helps in maintaining product quality and flow consistency. Whether it’s transferring lubricants in an automotive plant or moving viscous liquids in a chemical factory, Rotary Gear Pumps perform with precision.

How Rotary Gear Pumps Boost Productivity

When machines run smoothly, productivity goes up. The Rotary Gear Pump ensures that there is no leakage or wastage during operation. Its steady and controlled fluid flow keeps other connected machines working efficiently.

These pumps can handle thick or thin fluids easily, which means industries can use them for multiple tasks without needing separate equipment. This flexibility reduces downtime and saves maintenance costs.

In large-scale operations, time is money. Because Rotary Gear Pumps can operate continuously and reliably, they help industries meet tight deadlines without frequent shutdowns. This directly boosts overall productivity and keeps the work flowing at a steady pace.

The Role of Reliability in Industrial Performance

Reliability is the heart of any successful production system. A machine that fails often not only delays production but also affects the trust of customers and partners. The Rotary Gear Pump is designed for long-lasting reliability. Its gears are made with strong materials that can handle pressure, heat, and heavy loads.

Unlike other pumps that may struggle with thicker liquids, Rotary Gear Pumps perform consistently even under challenging conditions. They don’t lose suction power or get damaged easily. This makes them a trusted choice for companies that want dependable machines running around the clock.

Maintenance Made Simple

One of the best things about Rotary Gear Pumps is that they’re easy to maintain. Their compact design allows quick inspection, cleaning, and part replacement if needed. Because of their sturdy structure, maintenance is not required frequently, which saves time and labor costs.

Even if a minor issue occurs, it can usually be fixed without shutting down the whole system. This ease of handling keeps industries moving smoothly with fewer disruptions.

JEE Pumps – Setting New Standards in Pump Efficiency

When it comes to delivering quality and durability, JEE Pumps stands among the trusted names in the industry. With years of expertise, they design Rotary Gear Pumps that work perfectly for both small and large-scale industrial needs. Their products are known for consistent performance, energy efficiency, and long-term durability, helping businesses operate at their best.

How Rotary Gear Pumps Save Energy

Energy efficiency is one of the key advantages of using a Rotary Gear Pump. Because it operates with minimal internal friction, it consumes less power compared to other types of pumps. This helps industries reduce energy bills while maintaining high performance levels.

With the world moving toward greener solutions, energy-efficient machines are becoming essential. Rotary Gear Pumps not only improve operational output but also contribute to a more sustainable working environment.

Applications Across Industries

Rotary Gear Pumps are used in a wide range of industries. From oil refineries and food processing units to chemical plants and marine systems — their presence is everywhere. Their ability to handle different kinds of liquids, from thick lubricants to thin fuels, makes them a universal choice.

These pumps are also perfect for continuous processes where stopping is not an option. Their stable flow and durability help maintain product quality and prevent unnecessary waste.

Future of Rotary Gear Pumps

As industries continue to modernize, the demand for reliable and efficient fluid transfer systems is only going to grow. Rotary Gear Pumps are evolving too, with new designs that offer even better performance and energy savings. In the coming years, we can expect smarter, more compact, and environmentally friendly versions of these pumps to take the lead.

Conclusion

The Rotary Gear Pump plays a key role in helping industries run faster, smoother, and more efficiently. It brings together simplicity, durability, and high performance in one compact design. From reducing downtime to improving fluid handling accuracy, it’s a vital tool in modern industrial operations.

If your business is looking to enhance productivity and reliability, it’s time to consider upgrading to a high-quality Rotary Gear Pump. To get the best in design and performance, connect with JEE Pumps today and power your industrial systems with confidence.

source URL:https://postyourarticle.com/how-rotary-gear-pumps-improve-industrial-productivity-and-reliability/